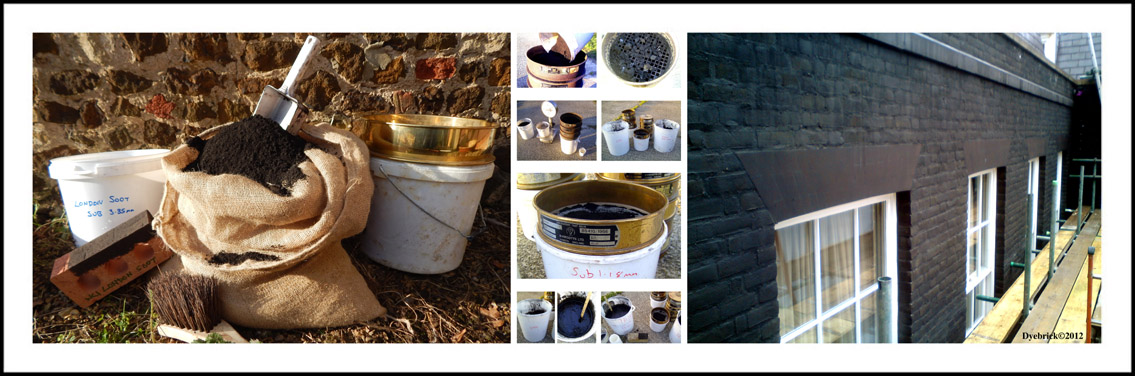

Soot Wash

Replication

Technical

A lot of traditional methods of producing soot washes, do not offer a durable finish, as the carbon deposits do not attach the same way as historical environmental pollutants. This results in rapid fade and 'wash off' from rain and natural weathering.

Soot Wash Replication is designed for use on new or mismatched brickwork and will produce significantly more durable results than standard soot wash solutions.

SOOT WASH Replication should only be used on untreated brickwork. It should not be applied to old blackened brickwork or brickwork that has previously been ‘sooted’. See our Carbonold website for more information.

Soot Wash Replication: Product Description (Mixed Product)

The patented Dyebrick tinting system is a low viscosity, water-based solution of modified mineral silicates, together with finely dispersed, micronised ferric oxide pigments, conforming to BS EN 12878:2005 (British European Standards Specifications). Soot Wash produces a similar colour to historical lampblack* chosen for its propensity to produce a close match to traditional historical soot washes**.

*LAMPBLACK - IMPORTANT NOTE:

Most lampblack or Lamp Black available on the market are too blue, and will not produce anything near a traditional soot wash. The majority are actually Furnace Blacks which are more likely to produce blue tones and not black. The particles are also far too fine and will leach or wash from the brickwork in a short period of time.

We take great care in sourcing the correct grades and colour test all our pigments against approved London sootwash brick panels.

There are no animal derived ingredients in any of our products.

FOR SUBTLE AGEING - PLEASE USE SEE OUR BRICK-AGE WEBSITE.

Dyebrick is non-toxic, non-flammable and odourless.

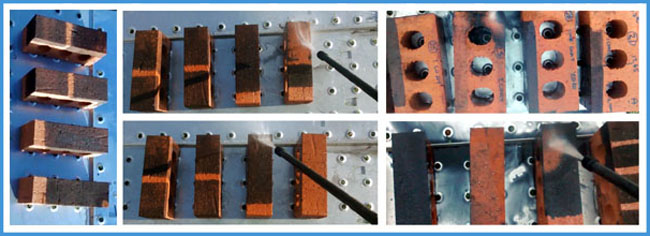

The Tinting System is designed to preserve the appearance of the substrates to which it is applied, whilst correcting colour defects and enhancing the existing surface. For this reason, the product is specifically formulated to maintain maximum translucency, not to hide the texture or appearance of the substrate and should not be confused with proprietary masonry paints and their associated maintenance commitments.

Dyebrick is formulated to achieve a high degree of penetration; this does not produce a film-forming coat, but reacts chemically with the masonry substrate to produce an insoluble, microcrystalline silicate bond.

The Tints create natural weather resistance by producing a semi-permeable membrane, which allows the structure to 'breathe'.

The original surface texture of the brickwork or masonry is not altered by this process the only evident effect is the designed colour change.

This tinting system has been used industrially for over forty years with great success, and potassium silicate paints have been applied to brickwork and masonry in various forms for over one hundred years.

** Refer to: The Complete Brick Tinting Manual - Chapter 5 (Special Applications) : "Traditional Soot Washes and Replications"

©2004-2015 Dyebrick Technical Services.

Chemistry of the System

Cementitious materials that have not fully hydrated contain un-reacted calcium hydroxide (CaOH2). Our pure mineral silicates reacts with this to form calcium silicate hydrates that are much harder. When applied to brick and masonry, this system not only relies upon the loss of water by evaporation and suction of the substrate, but also the reaction with atmospheric carbon dioxide and oxygen. Internal crosslinking between the silicate and alkaline components within the masonry also takes place during water depletion.

Reactions take place with other elements within the masonry. These may include silica (from the sand), ceramics (within the brick) and various metallic compounds (from sand/brick/stone) increasing durability further.

A micro-silicate bond is created within the matrix of the system (this process is called silification), which has extreme resistance to attack by the atmosphere and other corrosive elements.

Dyebrick is totally non-flammable and is totally inorganic in nature, having no Volatile Organic Compounds (Zero V.O.C.s). It has no combustible or harmful decomposition products during a fire situation, and is useful for formulations having to comply with BS 476 Spread of Flame.

Potassium Silicates are also outstanding for their resistance to biodegradation. They are alkaline in nature and are resistant to mould and algae.

©2004-2015 Dyebrick Technical Services.

VAPOUR PERMEABILITY

EUROPEAN VAPOUR PERMEABILITY AND SD VALUES.

Paints with an Sd value below 0.14m are considered to be Class 1 Vapour Open and to have high breathability performance.

Soot Wash Replication has a rating less than Sd 0.05m. When applied to brick and tile the permeability of the surface remains virtually unaltered. Any loss in permeability is too small to measure.

ZERO VOLATILE ORGANIC COMPOUNDS (VOCs)

Soot Wash Replication contains zero VOCs.